A mystery breakdown nearly halted operations for an industry leader. Could your operators be experiencing the same issue?

One of the most common breakdowns is the hardest to solve. Discover how Leading infrastructure company faced risk of extended operational delays due to an insoluble breakdown…

Situation

On 3rd December, a leading infrastructure and manufacturing company reported a machine experiencing continuous downtime. The pot would start up, but no abrasive would come through the nozzle. The issue posed a risk of extended operational delays if not addressed promptly, alongside potential safety risk to operators, halting all workflow.

Action Taken

Our Total Care team were called for assistance, with engineer Paul David attending the site to carry out a full inspection of the machine. During the check, he identified a blockage in the recovery hose as the cause of the problem.

The blockage meant the abrasive couldn’t pass through, causing a build-up of pressure and abrasive in the hose, worsening the blockage. Paul cleared the blockage and informed the customer of the findings and the steps taken to resolve the issue. The machine was then handed back to the operator for normal use.

Outcome

The machine was fully operational within 2 hours of the engineer arriving on site, preventing what could have been weeks of downtime if the problem source was not identified.

“Your company’s quick response and Paul’s swift discovery to our issue, has really helped us out.”

How can you prevent this common issue with your machines?

Blockages are a common issue in blasting, and there are many preventable measures engineers can take to avoid this:

Use Proper Media: Ensure abrasive media is dry, clean, and properly sized for the blast pot.

Moisture Control: Regularly check for condensation in the blast pot, moisture is the #1 cause of blockages. Air dryers and moisture separators can be installed on the compression line to help prevent this.

Correct Pot Loading: Do not overfill the blast pot; leave space for air circulation. Fill slowly to prevent bridging or compacting of media.

Regular Maintenance: Inspect and clean valves, metering systems, and hoses frequently. Ensure you have a critical spares list set up, and Replace worn-out gaskets and seals to prevent leaks that can lead to uneven flow. Read our downtime prevention checklist here: Reduce downtime by managing spares effectively

Air Pressure & Flow Checks: Maintain consistent air pressure as per manufacturer specs. Check for air leaks that can reduce flow and cause media to settle or let in moisture. Our air consumption calculator is available here: Air Consumption Chart.

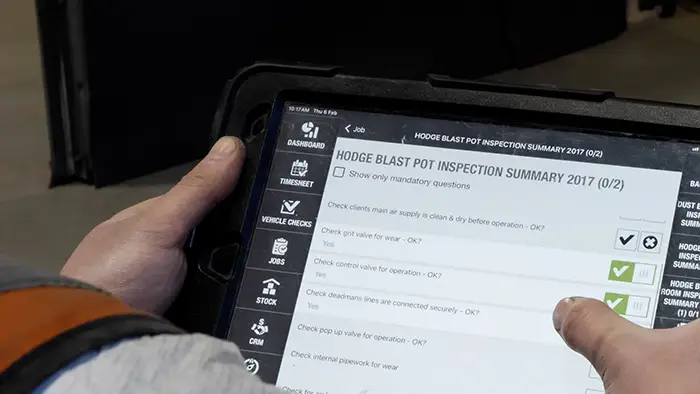

Preventive Inspections: Schedule routine checks for signs of media compaction or valve wear and keep a maintenance log to track issues before they escalate. A perfect way to track this is having a servicing plan to hand with a personalised spares package to your operation. View our total care packages and spares options here: Total Care

Operator Training: Train operators on proper start-up and shut-down procedures. Emphasise the importance of purging the pot after use to prevent leftover media hardening, causing a blockage in the hose or bottom of the pot. Our appreciation course for operators keep them safe and up to industry standard: Blast Cleaning Appreciation Training

Want to avoid costly delays and unexpected downtime? Our Total Care team is here to help! Call us on 0114 254 1505, or speak to our Sales team on 0114 254 0600.

For more tips on preventing breakdowns and setting up your blast pot correctly, visit www.surfaceprep.co.uk, where you’ll find answers to common call-out enquiries and best blasting practices.

Summary

- Issue: Machine downtime caused by recovery hose blockage.

- Resolution: Engineer cleared blockage and restored machine functionality.

- Timeframe: 2 hours from arrival on site.

- Impact: Avoided significant downtime and disruption.

- Avoid: How to prevent this issue with your operations.