Why small delays become big problems

Every idle hour costs more than labour. You lose booked hours, push back inspections, and burn operator confidence. The pattern is consistent in blasting: nozzles wear, seals harden, lenses fog, deadman circuits split, cartridges clog. None of this is a surprise. All of it is preventable with a simple parts plan.

“It is easy to prevent, a nozzle worn past spec or a tired pop-up seal that should have been swapped weeks ago. If the part is on the shelf, you are back up in minutes.”

What this guide gives you

- A practical framework to move from reactive fixes to planned uptime

- A short, defensible list of spares that stop the common failures

- Buying and stocking options that protect cash without risking downtime

Build a Critical Spares Pack per asset:

Blasting is abrasive by design. Portable pots, cabinets and rooms will wear. Catastrophic failures are rare. Most downtime comes from parts you can replace in under 30 minutes if they are to hand.

Treat spares as a reliability system, not a shopping list

- Flow path: venturi nozzles, nozzle retainers, blast hose sections, couplings, gaskets

- Control path: deadman handle, control hoses, RMS valve repair kit, regulator and gauge

- Visibility path: cabinet window lenses and tear-offs, helmet lens stacks

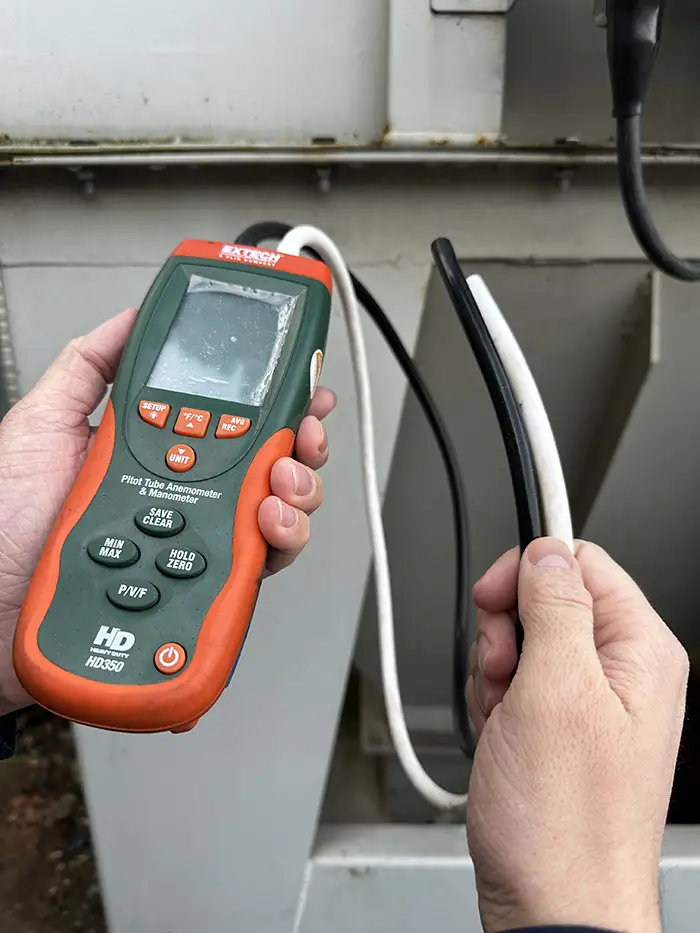

- Extraction path: dust cartridges, bin seals, differential pressure gauge

- Compliance path: breathing air filter elements, test kit access

The cheapest part in the system can take the whole cell down. We size packs to your duty cycle so the first fix is the only fix.

“A simple worn coupling gasket that should be checked daily that costs around £2.00 and takes less than a minute to check or replace can soon wear though causing damage to a £20.00 coupling and stop you from blasting.”

Planning beats emergencies every time

Rush orders, premium couriers and engineer call-outs cost far more than holding the right wear parts.

Make three decisions now:

- Stock policy: define Standard Spares (top-ups between services) and Critical Spares (items that stop production).

- Reorder triggers: use simple min-max levels tied to shifts and change-out intervals.

- Ownership: name a single owner for the spares shelf, with a weekly five-minute check.

SurfacePrep options to reduce risk and cash tied up:

- Critical Spares Packs tailored to your pots, cabinets and rooms

- TOTALCare service with fitted parts, inspection reports and planned visits Critical Spares Packs tailored to your pots, cabinets and rooms

“By the time you're calling an engineer out, it’s usually too late and the blast set up has broken down completely, losing you time and money. Nine times out of ten it’s on worn parts which should have been changed weeks ago.”

Planned Maintenance in context

Planned maintenance, also known as scheduled maintenance, refers to routine inspections, servicing, and repairs that are scheduled in advance, based on time intervals, usage cycles, or other criteria. Unlike reactive maintenance, which is carried out in response to equipment failure, This style of maintenance aims to prevent breakdowns and extend the life of equipment.

This proactive approach to maintenance is a cornerstone of effective asset management. It ensures that all machinery and systems are kept in optimal working condition, thereby minimising the risk of unexpected downtime and costly repairs.

Key Benefits of Planned Maintenance

Increased Equipment Lifespan

One of the most significant benefits of planning maintenance beforehand is the extended lifespan of your equipment. Regular servicing and timely repairs ensure that each component of your machinery operates at its best, reducing wear and tear. Over time, this leads to fewer breakdowns and the need for fewer replacements, ultimately saving money. By addressing potential issues before they become major problems, maintenance can help you get the most out of your investment in equipment, delaying the need for costly replacements.

Reduced Downtime and Disruptions

Unexpected equipment failures can bring production to a halt, causing significant disruptions to your operations. Planned maintenance helps prevent these disruptions by ensuring that machinery is serviced before it fails. By scheduling maintenance during off-peak hours or when equipment is not in use, businesses can keep operations running smoothly without the risk of unplanned downtime.

This proactive approach not only ensures continuity in operations but also improves overall productivity by reducing the frequency and impact of equipment failures.

Cost Savings

While planning maintenance could involve some upfront costs for inspections and servicing, it often results in substantial longer-term savings. By preventing major breakdowns, businesses can avoid expensive emergency repairs and the high costs associated with unplanned downtime. Moreover, maintaining equipment in good working condition reduces energy consumption, leading to lower utility bills. Additionally, companies can better manage their maintenance budgets by spreading out costs over time rather than facing sudden, large expenses when equipment fails unexpectedly.

Improved Safety

Safety is a paramount concern in any workplace, especially in industries where heavy machinery is used. Equipment that is not properly maintained can become a hazard to employees, leading to accidents and injuries. Planned maintenance (read more here: https://www.welchinstrumentation.co.uk/planned-maintenance/ ) ensures that all safety protocols are followed and that machinery is kept in safe working condition. Regular checks and maintenance of safety systems, such as brakes, alarms, and emergency shut-off systems, help prevent accidents and create a safer work environment for everyone.

Compliance with Regulations

Many industries are subject to strict regulations regarding the maintenance and safety of equipment. Failure to comply with these regulations can result in hefty fines, legal action, or even the shutdown of operations. Planned maintenance helps businesses stay compliant with these regulations by ensuring that all necessary inspections and repairs are carried out on time. By adhering to maintenance schedules and documenting all work performed, companies can demonstrate compliance during audits, reducing the risk of penalties.

Enhanced Efficiency and Performance

Well-maintained equipment performs better. Planning maintenance beforehand ensures that all components are functioning optimally, which can lead to improved efficiency in operations. For example, a well-tuned blastroom will consume less abrasive, and a properly calibrated machine will produce higher-quality outputs. Increased efficiency translates to better overall performance, higher production rates, and improved product quality, all of which can give your business a competitive edge. Planned maintenance is an essential strategy for any business that relies on machinery and equipment. By adopting a proactive approach to maintenance, companies can enjoy a range of benefits, including increased equipment lifespan, reduced downtime, cost savings, improved safety, regulatory compliance, and enhanced efficiency.

“Investing in maintenance is not just about keeping your equipment running; it’s about optimising your operations, ensuring safety, and ultimately contributing to the long-term success of your business. By taking the time to plan and implement a comprehensive maintenance schedule, you can avoid the headaches of unexpected breakdowns and enjoy the peace of mind that comes with knowing your operations are running smoothly. Get in touch with our team today to see how we can help.”

Do not let cheap lookalikes compromise the process

Third-party “equivalents” often miss on materials, tolerance or fit. A poor pop-up seal leaks, a soft liner erodes, an off-spec regulator drifts. You lose pressure, burn media and risk safety.

Engineer’s rule of thumb: only deviate from OEM or proven equivalents when the material spec, dimensions and operating range are documented and field-tested. If you cannot evidence that, do not fit it.

“Cheaper alternatives often lack durability causing premature wear and tear. They require more frequent replacement which leads to poor performance and downtime. We recommend fitting original Surfaceprep parts to provide better performance, increased efficiency and lower overall costs.”

A simple spares framework you can deploy this week

Step A: Audit

- List every blast asset with machine ID

- For each, log nozzle size, hose ID and length, media type, compressor CFM, dust collector model, helmet model and count

Step B: Classify parts

- A-items, stop the line: nozzles, RMS valve kits, deadman handles, control hoses, cabinet lenses, dust cartridges

- B-items, slow the line: hose sections, couplings, regulators, window gaskets, bin seals

- C-items, convenience: tools, fasteners, signage

Step C: Size the pack

- Light duty: 60 days of A-items, 1 set of B-items

- Standard duty: 90 days of A-items, 1–2 sets of B-items

- Heavy duty: duplicate the critical control chain for a true first-time fix

Step D: Control and replenish

- Label shelves by machine ID

- Set min-max levels and reorder points

- Review weekly, reconcile monthly

What to keep on the shelf, specifically

- Nozzles: 2–4 venturi nozzles matched to compressor and media, with retainers

- Blast hose path: one pre-made hose assembly per common run, plus coupling set

- Control path: 1 x deadman handle, 1 x RMS repair kit, control hose set, pressure regulator and gauge

- Visibility: cabinet window covers and inner lenses, helmet lens stacks and gaskets

- Extraction: spare dust cartridges sized to your collector, bin liner and seal set

- Compliance: breathing air filter cartridges, air quality test plan and records

- Room recovery: scraper floor blades or screw bearings where fitted

If you use wet or slurry blast, add the water injection nozzle kit and pump spares. If you do internal pipe work, add spare deflectors and Spinblast nozzles for your common diameters.

“Parts failing don’t just happen overnight. All the signs are there if you know what to look for. Nine times out of ten, we can see it coming. If the needed parts are on the self, or in our vans, you are back up and running the same day.”

Predictability is the real win

Operators work faster when they trust the kit. Managers make better promises when they can see the risk. Customers remember on-time delivery. A planned spares system gives you all three.

“The SurfacePrep team understood exactly what we needed. David, the engineer, did a great job, and the cabinet works brilliantly.”

Book your Spares Audit

We will map your assets, specify a right-sized Critical Spares Pack per machine, and propose Standard Spares top-ups or consignment stock where it helps cash flow. You get a bill of materials by machine ID, with quantities, part references and change-out guidance.

No obligation. No fluff. Just a clear path to more productive hours.

0114 254 0600