Choosing the wrong blasting setup can cost you more than time. It can delay projects, damage throughput, inflate abrasive waste, and breach HSE compliance. Whether you’re in aerospace, automotive, marine, or heavy manufacturing, the right blast system should reduce risk, protect your people, and optimise every shift.

This blog breaks down the key differences, and helps you make the right call first time, every time.

Cabinet or Room? The Decision That Shapes Your Output

Blast Cabinets are compact, enclosed systems ideal for precision finishing of small to medium parts. Operators load manually and blast through glove ports, making these perfect for clean zones, prototyping, and batch work.

Blast Rooms are full-scale walk-in or drive-in enclosures engineered for large or awkward components. Operators work inside the room using air-fed suits, with full systems for abrasive recovery, airflow, and dust extraction.

When to Choose a Blast Cabinet

- Small to mid-sized components up to 3 metres

- Controlled environments with cleanroom standards

- Intermittent or low-to-mid volume production

- Situations where dust containment is critical

Cabinet Advantages That Cut Risk and Boost Throughput

Precise And Protected

Cabinets like the SurfacePrep SmartCab offer 3–7 bar blast pressure, interlocked doors, and internal dust control, delivering consistent finishes while protecting operator health.

Media Flexibility

Compatible with glass bead, aluminium oxide, plastic media and more, SurfacePrep cabinets let you switch between jobs without retooling.

Fast Setup To Reduce Downtime

Delivered pre-assembled and production-ready within two hours. Plug in, blast, move on.

Clean, Safe Working

Built-in cartridge dust collectors maintain visibility, airflow and compliance with air quality regulations, all within a compact footprint.

When to Choose a Blast Room

- Oversized components (e.g. rail, steel frames, turbines)

- High-throughput production needs

- Full-site blasting where operator access is vital

- Goals around media recycling and cost per blast

Blast Room Benefits That Pay Back Every Shift

Built to Fit, Built to Scale

Each room is custom-engineered to your site and production flow. Choose acoustic booths, reverse-pulse dust extraction, overhead cranes or integrated media recovery systems, all designed to work as hard as your team.

Compliance Engineered In

SurfacePrep blast rooms support LEV testing, pressure vessel certification, and HSE-compliant monitoring (PSSR 2000) from day one.

Operator Protection, Built-In

Apollo 600 air-fed helmets, flame-retardant suits and RPE kits ensure safe operation, wet or dry.

Sustainable Abrasive Recovery

From magnetic separators to bucket elevators and floor reclaim systems, SurfacePrep helps reduce abrasive waste and lower long-term cost per blast.

FAQ: Choosing Between Blast Cabinets and Blast Rooms

A blast cabinet is a self-contained unit designed for smaller parts and precision work, typically operated via glove ports. A blast room is a walk-in enclosure for large or heavy components, where the operator enters the space wearing full PPE and uses a blast hose directly.

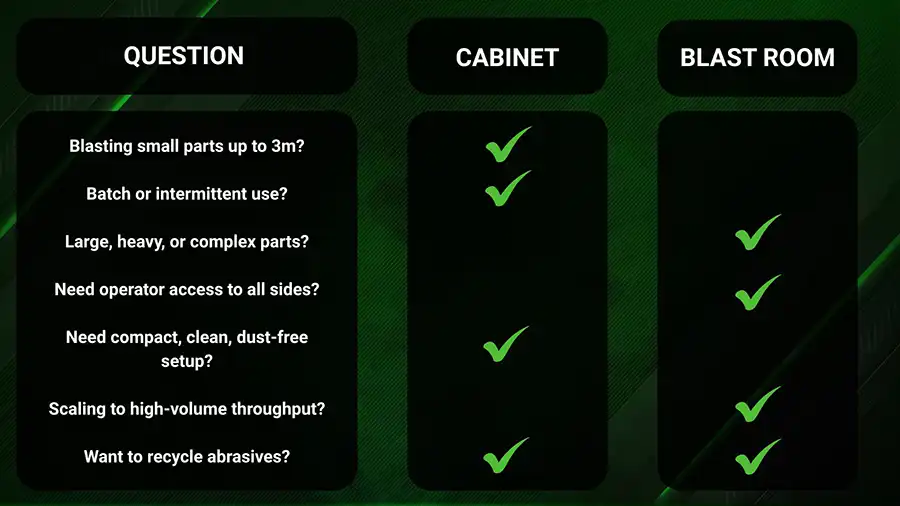

Still Deciding? Use This Quick Filter: