Abrasive blasting PPE is not just the kit you wear. It is a complete system that only protects the operator when the helmet, breathing air supply, suit, checks, maintenance, and records work together.

In real blasting conditions, the operator can be exposed to airborne dust, ricochet, high noise, heat stress, and respiratory risks that change quickly with the environment, extraction performance, abrasive media, and the condition of the compressed air system.

This guide explains what good looks like in practice, with a simple structure you can use on site: hazards → controls → checks → evidence.

At a glance: the four things auditors and managers look for

- The PPE category matches the job hazards, not “what we used last time”.

- Air-fed respiratory protection is treated like life support, not a box-tick.

- Consumables and components are maintained to a defined routine, not “when it looks worn”.

- Records are retrievable, showing what was checked, when, by whom, and what happened when something failed

Start with a hazard map, then choose the PPE and RPE category

A common failure mode in blasting is selecting PPE based on habit. “Good” starts with a job-specific hazard map, because blasting risk varies by:

- abrasive type and dust generation

- substrate and coating (what becomes airborne when hit)

- open blasting vs cabinet vs blast room

- ventilation or extraction performance

- wet vs dry process conditions

- breathing air system design and condition

The five hazard buckets most blasting jobs create

Respirable contaminants

Dust and fine particulate are the obvious risk, but exposures can shift fast with the job and the controls in place. If you can “see” dust, you already know the risk is not theoretical. If you cannot see it, that does not automatically mean it is controlled.

Impact and abrasion (ricochet and ingress)

Ricochet is predictable. “Good” PPE means full coverage and strong protection in high-wear zones, plus closures that reduce abrasive ingress at wrists, ankles, and neck.

Noise

Blasting noise is not a side issue. It drives fatigue, communication errors, and unsafe shortcuts. “Good” setups plan hearing protection that fits the helmet system and still allows clear communication.

Heat stress and comfort under load

Discomfort becomes risk when it triggers behaviours like visor up, hood off, rushed work, and skipped checks. Comfort features are safety features on long blasting shifts.

Air supply failure modes

Air-fed blasting helmets only protect when the air is safe and delivered at the required flow and pressure. Failures can develop quickly, and the operator may not notice until protection is already compromised.

Respiratory protection in blasting: do not separate the helmet from the air system

If blasting generates airborne contaminants, an air-fed blasting helmet is part of the respiratory protective device (RPD) strategy. But “good” is not “we bought helmets”. Good is a system.

Helmet performance in real conditions: sealing, visibility, and usability

In practice, RPE fails when usability fails. If the visor fogs, if the lens etches, if airflow feels “a bit low”, operators compensate. Those compensations are where exposure and incidents start.

What to look for in an air-fed blasting helmet setup

- Airflow indication: a clear low-airflow warning so loss of protection is visible during work.

- Lens and latch resilience: multi-lens approach, robust latch and rim design to reduce ingress and keep lenses secured.

- Maintainable hygiene points: cape systems that can be removed, cleaned, and replaced to reduce leakage and contamination build-up.

- Replaceable components: parts you can swap quickly so downtime does not drive unsafe “make it do” behaviour.

Breathing air quality is a life support problem, not a compliance box

If you are relying on air-fed PPE, your compressed air system must be treated as a controlled safety system.

Common failure modes that can compromise breathing air include:

- intake contamination from vehicle exhaust or local processes

- compressor faults that can generate dangerous gases

- filtration reaching end of life, passing oil or water

- dryer faults and moisture issues

- freezing or blockages affecting demand valves

- insufficient flow or pressure reducing protection

Important clarity point: sensory checks (including smell) may be part of a process, but they are not a substitute for formal testing and control. SurfacePrep engineers are fully trained to ensure safety and compliance.

Testing cadence and record-keeping: evidence matters

Good PPE systems stand up to scrutiny because they can prove control, not because they promise it.

What “good” evidence looks like:

- a defined testing cadence that matches the risk assessment and site requirements

- documented results that are easy to retrieve

- clear corrective actions when a test or check fails

- maintenance routines aligned to manufacturer guidance for hoses, filters, and helmet components

If your documentation states baseline testing intervals (for example “every three months”) and retention periods (for example “five years”), present them as baseline guidance from your own system, then reinforce that risk assessment, site rules, and auditor expectations may require more.

Safety systems outside “PPE” that make PPE work

In blasting environments, safety is not only worn. It is engineered into the work area and the equipment.

Examples of engineered controls that reduce reliance on perfect human behaviour:

- door interlocks on blast cabinets to prevent blasting with doors open

- blast room viewing windows so supervisors can monitor progress without unnecessary exposure

- man-down alarm logic that disables blasting or recovery if the operator does not reset within a set time

- emergency stop systems designed for fast intervention

- tamper controls that prevent unsafe changes to regulators or metering settings

These controls matter because they reduce the chance that a single missed step becomes an incident.

Blast suits: match protection to the process, not the catalogue

A practical suit selection rule:

- If ricochet is the primary risk, prioritise impact protection in the zones that actually get hit.

- If the environment introduces ignition or flame risk, you need the correct FR category plus the site controls and procedures.

- If heat stress limits safe working time, comfort and cooling features are safety features.

If you cite standards such as EN ISO 14877 (blasting protective clothing) or BS EN ISO 11612 (heat and flame), make the reader benefit explicit: what changes in inspection, selection, and suitability because of that standard.

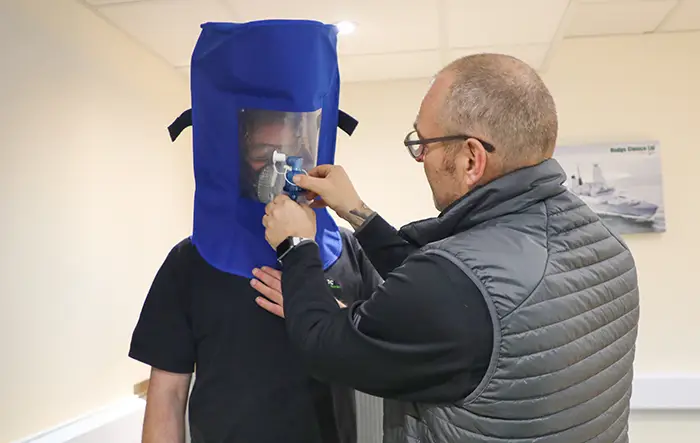

Training: the gap between “issued PPE” and “used properly”

Even high-quality blasting PPE fails without training and discipline. Good training covers:

- correct fitting and adjustment

- airflow checks and what to do when low flow is indicated

- lens, seal, and cape inspection habits

- replacement routines aligned to manufacturer guidance

- how breathing air testing fits the risk assessment and records system

A useful way to frame this is: training reduces operator variability and prevents “normalisation of deviance”, where unsafe work becomes the accepted way.

A practical audit checklist: what to check this week

Use this checklist to surface gaps fast:

- Do air-fed helmet users have a defined breathing air testing frequency based on risk, and is it being followed?

- Are test records retrievable, showing what was tested and the result?

- Do helmets have an in-service inspection routine for lenses, seals, cape condition, and airflow indicators?

- Are blast suit types matched to process risk, including FR needs where relevant?

- Do engineered safety systems exist (interlocks, emergency stop, man-down), and do people actually use them?

- Are hoses, filters, and consumables changed in line with manufacturer guidance, with evidence?

Where SurfacePrep fits into your system

If you want to turn blasting PPE into an operator safety system, the key is joined-up thinking: helmet and suit selection, breathing air controls, testing and records, and training.

If you want a documented review of your blasting PPE and breathing air controls, including what to test, how often, and what evidence to keep, speak to SurfacePrep’s team, email us to book a PPE Review

FAQs

What PPE is required for abrasive blasting?

Depends on process (open blasting, cabinet, blast room), abrasive, substrate/coating, and control measures. At minimum you are usually managing respiratory risk, ricochet, noise, and contamination ingress. Tie selection to a job hazard map.

Is an air-fed blasting helmet classed as respiratory protective equipment (RPE)?

In practice it forms part of the RPD strategy when airborne contaminants are present.

How often should breathing air be tested for air-fed blasting helmets?

Set frequency by risk assessment, site rules, and equipment condition. If you publish a baseline interval, label it as baseline guidance and state when “more often” applies.

Can you rely on smell to judge breathing air safety?

No. Sensory checks can be one layer, but they do not replace testing, filtration control, and documented evidence.

What are the most common failures in blasting PPE systems?

Low airflow, degraded filtration, worn hoses, damaged seals and capes, etched lenses, poor maintenance routines, and missing records.

What standard applies to blasting suits?

Commonly EN ISO 14877:2003 is referenced for blasting protective clothing.

Why do interlocks and man-down systems matter if the operator has PPE?

They reduce reliance on perfect human behaviour and prevent one failure becoming an incident.

What records should I keep for blasting PPE and breathing air controls?

Keep inspection logs, test results, maintenance and filter changes, non-conformance actions, and training records, in a format you can retrieve quickly.