Independent studies state 70-80% of coating failures are not product failures. They are surface preparation failures earlier in the production cycle.

This guide shows engineers and paint shop leaders how to design, run, and verify powder and wet paint systems that reduce rework, raise first-pass yield, and keep compliance airtight.

If your finish fails, the root cause usually sits way before you reach the booth. Oils left on the substrate, poor conversion coating control, dew point ignored, or unstable cure time will defeat even the best powder or paint. The result is more time spent on rework, warranty costs, risk to your schedule and audit exposure.

At SurfacePrep, our aim is to provide you with a clear, proof-led path to developing robust powder and wet paint processes that deliver consistent appearance, adhesion and corrosion resistance.

Diagnosis first

Our engineers are trained to understand how defects present themselves, where to look first, and how to separate prep issues from application errors. We then map the pre-treatment routes that bond, not just clean: degrease, mechanical profile where required, and the right conversion coating for the substrate and duty. From there, we break down booth design and airflow control for powder and wet paint.

- For wet paint, understand the differences between dry-filter and water-wash booths.

- For powder, design reclaim and cartridge filtration correctly and choose colour-change logic that matches your mix.

Environmental control

For wet paint, track relative humidity, temperature and dew point, and use the substrate-to-dew-point rule to prevent condensation under coats. For powder, profile ovens, measure part temperature not just air, and verify cure consistently. We cover application setup and film build control in parallel. For wet paint, get atomisation, tip selection and hose ID right, with airless capability for heavy-duty marine and industrial coatings. For powder, set kV and microamps, prove grounding, understand Faraday areas and gun-to-work distance, and tune line speed for wrap and coverage.

Finally, we standardise quality, safety and compliance. That means breathing air quality testing to EN12021, documented LEV examinations, Written Schemes of Examination for pressure systems, and operator training with planned servicing and spares. Together, these controls reduce unexpected downtime and make audits routine rather than stressful.

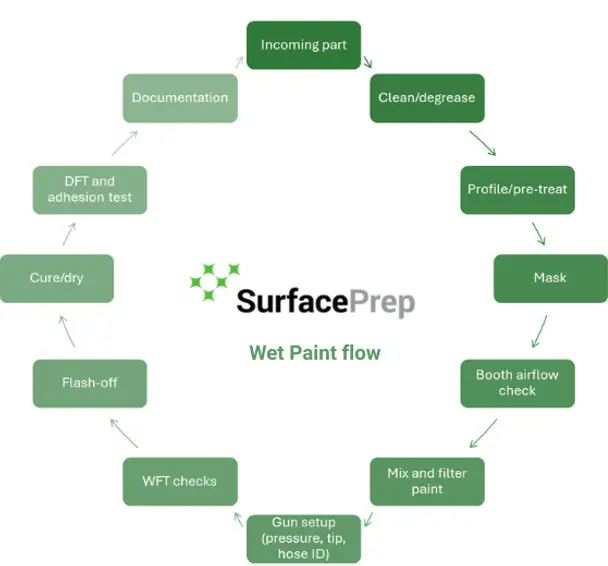

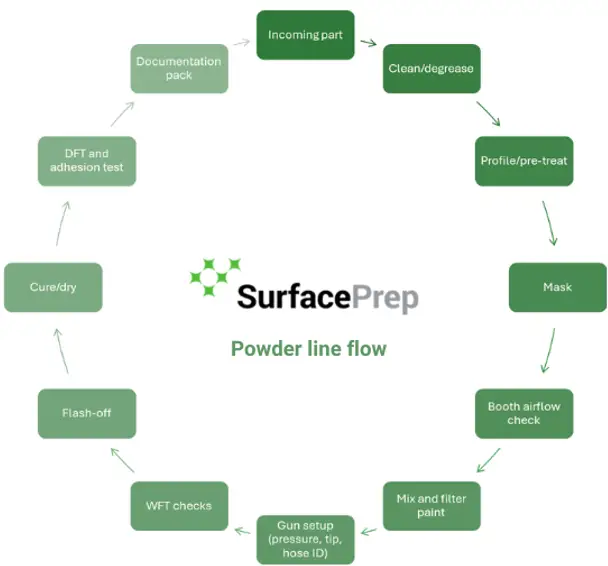

Throughout, we cite the SurfacePrep system pages and approved PDFs for proof and further reading, and include practical tools: troubleshooting tables, QC cheat-sheets, and environmental control boxes for both powder and paint. Two flow diagrams show the end-to-end steps for wet paint and powder lines, making it easy to align people, equipment and checks.

Outcomes you should expect after implementing this approach

- Lower rework and scrap through stable pre-treatment and film build control

- Higher first-pass yield via correct booth/airflow, grounding and cure verification

- Safer, compliant operation with EN12021 air testing, LEV records and pressure system controls

- Faster colour changes and fewer stoppages through reclaim and changeover logic

- Clear, auditable documentation that accelerates customer approvals

This is how to stop blaming the paint and start running a process that delivers every time.

Main Guide

1) Why most finishes fail: diagnose the real mechanisms

When paint peels, blisters or lifts, the primary cause is usually upstream: contamination, poor conversion coating, or environmental control. For powder, issues like poor wrap, back-ionisation marks or edge pull-back often trace to grounding, Faraday geometry, or cure. Start with a failure map: identify whether defects originate in surface prep, application, or cure.

What to check first, both processes

- Cleanliness of substrate (oils, salts, shop soil)

- Profile and conversion coating parameters

- Booth airflow direction and stability

- Environmental conditions vs dew point (paint)

- Grounding and electrostatics (powder)

- Oven profile: air vs part temperature and dwell time (powder), flash-off and cure windows (paint)

2) Surface preparation and pre-treatment that bonds

Wet Paint and Powder, in parallel

- Degrease: Remove oils and contaminants before any mechanical or chemical step.

- Mechanical key (where required): Abrasive blast or similar, to create profile for adhesion.

- Conversion coating: Select iron or zinc phosphate, chromate/chromate-free, oxalate, or anodising according to substrate and duty cycle. Map stages, temperatures and dwell, then verify.

Auto wash units and lines

Automated spray/dip pre-treatment can be 2–4 stages upward, configured to your substrate and performance standards, with automatic cycling and dry-off integration. Document stage controls and specify test methods for cleanliness and coat weight.

3) Booth design and airflow control

Wet Paint booths

- Dry-filter booths: Concertina paper media captures overspray; exhaust to atmosphere. Choose media type to match paint.

- Water-wash booths: Vertical water wall captures overspray; scrubber returns contaminants to water, then through eliminators before exhaust. Stainless base tank, mesh screens, and dual extraction keep airflow stable.

Powder booths

Powder booths use cartridge filtration behind perforated screens. Pulse-clean filters, reclaim where colour mix allows, and duct the now-clean air back to room or out to atmosphere. Plan colour-change logic and cleaning to match SKUs and takt time.

See also SurfacePrep’s dedicated powder booth guidance and FAQs for multi-colour options and compliance expectations.

4) Environmental control

Wet Paint

Control RH, air movement and booth temperature. Always check substrate temperature vs dew point and avoid coating when the substrate is at or below dew point plus your site safety margin. Use drying rooms or low-temperature ovens after pre-treatment to stabilise parts.

Powder

Cure ovens must be profiled for part temperature, not just air. Typical powder cure temperatures sit around 180–200°C with appropriate dwell; box ovens and conveyorised cure/dry-off ovens can be configured to your loading, burner/electric heat, and insulation specification. Verify uniformity and record first-off runs.

5) Application setup and film build control

Wet Paint

Get atomisation and delivery right. For protective and marine duty, specify airless equipment with ratios and max tip sizes suited to high-solids, high-build coatings. Select hose ID to maintain flow and minimise pressure drop. Use appropriate guns, guards and tips and maintain air-fed RPE with compliant breathing air.

WFT/DFT control

Target WFT is driven by solids by volume. Use a simple gauge routine and record WFT at start, during, and at end of runs. Confirm DFT post-cure.

Powder

Set electrostatics and motion: kV and microamps per manufacturer guidance, constant gun-to-work distance, and verified grounding of parts and hangers. Tune line speed for coverage and wrap, and adjust technique in Faraday areas. First-off checks verify coverage and edge protection before committing the batch.

6) Flash-off and cure schedules, and verification

Wet Paint

Respect flash-off and recoat windows. Manage solvent entrapment risk with airflow and time, then cure as specified. Record oven setpoints and part temperatures for each batch, and verify DFT and adhesion.

Powder

Measure gel time, confirm part temperature has achieved the specified cure schedule, and use production oven profiling to hold stability. Verify cure with first-off checks and retain records.

7) Quality control, compliance and safety

- Breathing air quality to EN12021: Test at least every three months, and more often based on risk or when compressors move or conditions change. Retain records for five years. Consider continuous monitoring and appropriate filtration options.

- LEV examination: At least every 14 months, with records retained five years, per HSE guidance.

- Pressure systems: Maintain a Written Scheme of Examination and test to the periodicity defined in your WSE.

- Training, servicing and spares: Use operator training, planned maintenance, and critical spares to prevent downtime and stabilise QA. In-house and site options are available.

8) Technical tools and sidebars

Troubleshooting tables

Wet Paint defects (what to check first)

- Orange peel → Viscosity/atomisation, gun distance, booth temp/air movement, WFT too high.

- Fisheyes → Contamination (silicones/oils), cleaning stage, air filtration.

- Solvent pop → Flash-off too short, film too thick, booth temp too high.

- Runs/sags → Excess WFT, technique, too slow solvent cut.

- Pinholes/blistering → Entrapped solvent or contamination, substrate near dew point, inadequate flash-off.

Powder defects (what to check first)

- Back-ionisation → kV too high, too close spray distance, charge build-up.

- Poor wrap → Grounding, line speed, gun-to-work distance, flow.

- Faraday cage effect → Reduce kV, reposition guns, adjust flow/angle.

- Craters → Oil/silicone contamination, compressed air quality.

- Outgassing pinholes → Pre-bake components, adjust cure.

- Edge pull-back → Film build too high at edges, flow and grounding.

QC cheat-sheets

Wet Paint

- Wet Film Thickness (WFT) target = Dry Film Thickness (DFT) ÷ solids by volume. Use your comb gauge at the start/mid/end.

- Record DFT on calibrated gauge and adhesion checks on first-off.

- Log booth temp/RH, substrate temp and dew point delta before coating.

Powder

- DFT window per product TDS.

- Verify ground resistance of racks/hangers/parts before each shift. You will need to calculate your numeric target and method.

- Oven profile: log part temperature to spec dwell; keep first-off record.

- First-off coverage photos, including Faraday zones and edges.

Environmental control boxes

Wet Paint

- Keep substrate temp ≥ dew point + safety margin.

- Target RH window per coating system.

- Control air movement during flash-off to avoid skinning/solvent trap.

Powder

- Booth airflow stable; reclaim settings match colour load/mix.

- Oven profiling by part temperature; verify across worst-case mass.

Safety and compliance box (tag to approved PDFs only)

- EN12021 breathing air: test at least every three months; keep 5-year records. Consider BAK6100 for continuous monitoring and appropriate filtration stacks.

- LEV: thorough examination at least every 14 months; retain records 5 years.

- Pressure systems: maintain WSE and periodic testing per scheme.

9) Customer examples

- Automotive Tier-1 (powder): After stabilising phosphate stage chemistry and enforcing first-off DFT checks, rejects dropped, and line speed increased without loss of wrap.

- Marine heavy-duty (wet paint): Correcting pump ratio and tip selection improved wet-out and eliminated runs, cutting time spent on reworking every month.

- Fabrication job shop (powder): Reclaim and colour-change routine reduced changeover time and raised first-pass yield significantly

10) Light SurfacePrep integration

SurfacePrep designs and integrates complete finishing systems across powder and wet paint, including pre-treatment, booths, ovens, conveyors, and controls, with training, hire and TotalCare servicing to keep uptime and compliance on track.

If you want independent validation of your finishing line, contact us and book a Wet Paint and Powder Line Audit or a Pre-treatment Review. We will assess airflow, environmental stability, grounding, cure verification and compliance records, then leave you with a clear action plan.

Enquire here →

Call us on 0114 254 0600