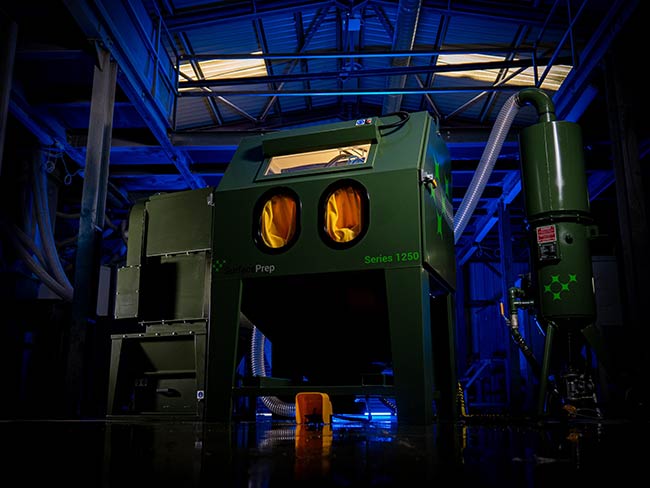

Pressure blast cabinets are essential when removing heavy corrosion, tough coatings or when high production rates are required. Cleaning rates are up to 5 times the speed of a suction cabinet and are suitable for use with all our recyclable abrasives. Pressure blast cabinets are commonly used in high production environments or on applications such as alloy wheel refurbishment and cleaning heavy castings

Applications

- Removing heavy corrosion & tough coatings.

- Suitable for use with all our recyclable abrasives

- Cleaning heavy castings.

- Alloy wheel refurbishment.

- Powder coating removal.

Features

- Large capacity pressure blast vessel.

- Vacuum recovery unit to minimise blockages in the machine.

- Abrasive regrader unit to allow for accurate media cleaning on a range of abrasive types.

- Pressure regulator for fine control of air pressure.

- Abrasive grit valve for accurate adjustment of media feed rate.

- Pneumatic foot pedal control for instant operation.

- Safety door interlock system which interrupts blasting operation in the event of any of the doors being opened.

- High capacity reverse pulse extraction unit to aid visibility and cleanliness inside the blast cabinet.

- Heavy duty internal rubber curtains.

- Fully-sealed ergonomically designed glove ports.

Downloads

Pressure Cabinet Owners Manual

IND800COMPXM Drawing

IND1000COMPXM Drawing

IND1250COMPXM Drawing

IND1500COMPXM Drawing