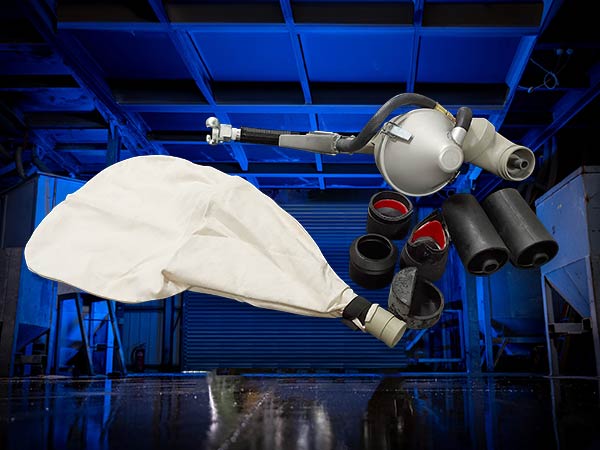

Blast Machines

SurfacePrep UK standard blast machines are the most technically advanced blast machines available, offering unrivalled performance, low running costs and extended life cycles. Our Contractor range has become the industry standard in performance, mobility, safety and quality of construction.

Blasting Machine Insights & Tips

SurfacePrep UK Ltd

36 Orgreave Drive

Sheffield

South Yorkshire

S13 9NR

Company No.: 13536703

Services

Products

Information